The world of silver jewelry is undergoing a quiet revolution as artisans and manufacturers seek solutions to one of the metal's most persistent challenges: oxidation. While silver's warm glow and affordability have made it a staple in jewelry boxes worldwide, its tendency to tarnish has long frustrated wearers and designers alike. Now, an innovative approach using rhodium-palladium alloys promises to redefine what we expect from silver accessories, offering unprecedented protection against discoloration while maintaining the metal's signature beauty.

For centuries, jewelers have experimented with various techniques to slow silver's natural reaction with sulfur compounds in the air. From protective lacquers to frequent polishing routines, these methods have all fallen short of providing a permanent solution. The introduction of rhodium plating in the mid-20th century marked a significant advancement, creating a bright white barrier that resisted tarnishing. However, this technique had its limitations—the thin rhodium layer would eventually wear away, requiring reapplication, and some wearers found the finish too cool compared to silver's natural warmth.

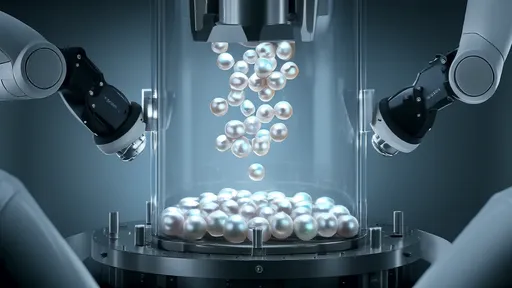

The breakthrough came when metallurgists began exploring alloy combinations that could provide oxidation resistance at a molecular level. Rhodium and palladium, both platinum group metals, emerged as ideal candidates due to their remarkable corrosion resistance and compatibility with silver. When blended in precise ratios and bonded with silver at high temperatures, these precious metals create a stable matrix that fundamentally alters how the material interacts with its environment.

Unlike surface treatments that can wear off, the rhodium-palladium alloy integrates throughout the silver piece during the manufacturing process. This creates what scientists call a "bulk modification" rather than just a surface coating. The resulting material maintains the workability and appearance of sterling silver while gaining the oxidation resistance of its more expensive cousins. Laboratory tests show these alloyed pieces resist tarnishing up to fifteen times longer than traditional sterling silver when exposed to identical conditions.

Beyond its practical benefits, this technological advancement opens new creative possibilities for jewelry designers. The enhanced durability allows for more intricate detailing that would previously have been vulnerable to oxidation in hard-to-clean areas. Designers report being able to create pieces with finer textures and more delicate features, knowing the metal will maintain its appearance over time. Some avant-garde collections are already showcasing these capabilities with elaborate filigree work and micro-engraving that would have been impractical with untreated silver.

The environmental impact of this innovation deserves attention as well. Traditional silver cleaning methods often involve chemical dips or abrasive polishes that generate waste. By dramatically reducing the need for these maintenance routines, rhodium-palladium alloyed silver offers a more sustainable option for eco-conscious consumers. Additionally, the extended lifespan of each piece means less frequent replacement, further reducing the jewelry industry's environmental footprint.

Manufacturing processes for these advanced silver alloys require precise temperature control and specialized equipment. Artisans must carefully monitor the cooling process to ensure proper crystallization of the metal matrix. While this adds complexity to production, industry leaders believe the superior performance justifies the additional effort. Several high-end silverware manufacturers have already begun incorporating the technology into their flagship lines, with plans to expand availability as production capacity increases.

Consumer response to these next-generation silver pieces has been overwhelmingly positive. Early adopters report satisfaction with pieces that maintain their luster despite daily wear and minimal maintenance. Retailers note that the premium pricing—typically 20-30% above traditional sterling silver—has not deterred buyers who value both the aesthetic qualities of silver and the practicality of tarnish-resistant materials. Market analysts predict rapid growth in this segment as awareness spreads and production scales up.

Looking ahead, researchers continue to refine the alloy formulas, experimenting with different ratios of rhodium and palladium to optimize both performance and cost. Some laboratories are exploring the addition of trace elements that could further enhance the metal's properties. As these technologies mature, we may see silver jewelry that not only resists tarnishing but also offers improved scratch resistance and even antimicrobial benefits.

The development of rhodium-palladium alloyed silver represents more than just a technical improvement—it signals a shift in how we value and interact with precious metals. By solving silver's most frustrating limitation, this innovation allows the metal's natural beauty to shine through without compromise. For jewelry lovers who have long adored silver's warm glow but dreaded the maintenance, this advancement may finally offer the best of both worlds: timeless beauty meeting modern durability.

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025