Germany has long been recognized as a global leader in precision engineering and advanced manufacturing, particularly in the field of medical-grade titanium processing. The country’s expertise in titanium surface treatment sets a benchmark for quality, durability, and biocompatibility, making it indispensable for medical implants, surgical instruments, and dental applications. The meticulous attention to detail in German titanium processing ensures that the material meets the stringent requirements of the healthcare industry, where even the slightest imperfection can have significant consequences.

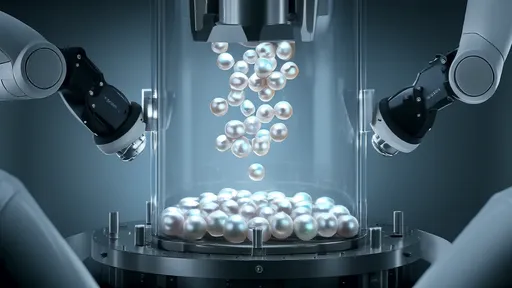

The journey of titanium from raw material to medical-grade component begins with rigorous material selection. German manufacturers source high-purity titanium, often Grade 4 or Grade 5 (Ti-6Al-4V), which are renowned for their exceptional strength-to-weight ratio and corrosion resistance. These grades are particularly favored in medical applications due to their compatibility with human tissue. The initial processing involves precision machining to shape the titanium into the desired form, whether it be a hip joint, dental implant, or spinal fixation device. However, the true magic lies in the subsequent surface treatments that enhance the material’s performance and longevity.

One of the most critical steps in German titanium processing is surface finishing. The goal is to create a surface that not only promotes osseointegration—the process by which bone cells attach to the implant—but also minimizes the risk of bacterial colonization. Techniques such as mechanical polishing, electrochemical polishing, and abrasive blasting are employed to achieve the desired surface roughness. For instance, a slightly roughened surface can improve bone adhesion, while an ultra-smooth finish might be preferred for components that interact with soft tissues. German engineers meticulously control these parameters to ensure optimal performance for each specific application.

Beyond mechanical finishing, advanced surface modification techniques are employed to further enhance the titanium’s properties. Plasma electrolytic oxidation (PEO), for example, creates a porous oxide layer on the titanium surface, which significantly improves its bioactivity. This layer mimics the natural structure of bone, encouraging faster and more stable integration with the patient’s body. Another innovative approach is the application of hydroxyapatite coatings, a calcium phosphate compound that is chemically similar to human bone. These coatings are often applied using plasma spraying or magnetron sputtering, techniques that German manufacturers have perfected over decades of research and development.

The German approach to titanium processing also places a strong emphasis on sterilization and cleanliness. Medical implants must be free from contaminants that could trigger immune responses or infections. To achieve this, manufacturers employ advanced cleaning protocols, including ultrasonic cleaning and passivation, which removes free iron and other impurities from the titanium surface. Additionally, gamma irradiation and autoclaving are commonly used to ensure sterility before the implants are packaged and shipped to hospitals and clinics. These steps are critical in meeting the rigorous standards set by regulatory bodies such as the FDA and the European Medicines Agency.

Durability is another hallmark of German titanium processing. Medical implants are subjected to constant mechanical stress, and their failure can have devastating consequences for patients. German manufacturers address this challenge through techniques like shot peening, which induces compressive stresses on the titanium surface, thereby enhancing its fatigue resistance. Furthermore, the use of additive manufacturing, or 3D printing, allows for the creation of complex, lightweight structures that are both strong and flexible. This technology has revolutionized the production of custom implants tailored to individual patient anatomy, a capability that German companies have been at the forefront of pioneering.

The environmental and sustainability aspects of titanium processing are also a key consideration in Germany. Titanium is a highly recyclable material, and German manufacturers have implemented closed-loop systems to minimize waste and energy consumption. The extraction and refining of titanium are energy-intensive processes, but advancements in recycling technologies have significantly reduced the carbon footprint of medical-grade titanium production. This commitment to sustainability aligns with Germany’s broader environmental policies and reinforces the country’s reputation as a responsible leader in advanced manufacturing.

In the realm of dental implants, German titanium processing has set new standards for precision and reliability. Dental implants require exceptionally smooth surfaces to prevent plaque buildup and ensure long-term stability. Techniques such as laser ablation and anodizing are used to create surfaces that are not only biocompatible but also aesthetically pleasing. The ability to produce implants that blend seamlessly with natural teeth while providing unmatched functionality is a testament to the ingenuity of German engineering.

The future of German titanium processing lies in the continued integration of smart technologies and materials science. Researchers are exploring the use of bioactive coatings that can release growth factors or antibiotics to further enhance healing and prevent infections. Nanotechnology is also being leveraged to create surfaces with unprecedented levels of precision and functionality. As these innovations mature, they will undoubtedly solidify Germany’s position as the global leader in medical-grade titanium processing.

In conclusion, Germany’s expertise in titanium surface treatment for medical applications is the result of decades of innovation, precision engineering, and unwavering commitment to quality. From material selection to advanced surface modifications and sterilization, every step in the process is meticulously controlled to meet the highest standards. As the demand for high-performance medical implants grows, German manufacturers are poised to lead the way with cutting-edge technologies and sustainable practices that benefit patients worldwide.

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025