The jewelry industry stands on the brink of a transformative era with the advent of micro-setting technology. What began as painstaking handiwork requiring master craftsmen to spend hours aligning tiny gemstones has now evolved into a precision-driven automated process. At the heart of this revolution lies the ability to automatically arrange 1mm gemstones with unprecedented accuracy—a feat that merges cutting-edge engineering with artistic vision.

For decades, micro-setting remained one of the most technically challenging techniques in jewelry making. The process involved securing minuscule diamonds or colored gems so closely together that the metal beneath became nearly invisible, creating a dazzling surface of uninterrupted sparkle. Traditional methods demanded not only exceptional skill but also inhuman levels of patience, as artisans worked under magnifiers to place each stone individually. The introduction of automated 1mm gemstone alignment doesn't just accelerate production—it redefines what's possible in design complexity and scale.

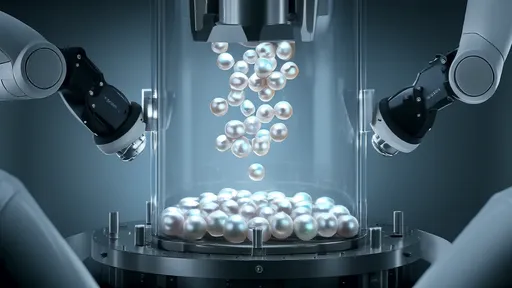

The precision required for 1mm gemstone automation borders on the microscopic. Advanced systems now utilize high-resolution vision technology combined with robotic arms that can pick and place stones with micron-level accuracy. This goes far beyond simple mechanization; it involves sophisticated algorithms that calculate optimal stone positioning based on cut, reflectance, and even the intended play of light across the jewelry piece. What emerges are settings so precise they challenge the limits of human visual perception.

Material science plays an equally crucial role in this technological leap. The metal alloys used in automated micro-setting require specific properties—enough malleability to secure each stone firmly, yet sufficient rigidity to maintain structural integrity at such minute scales. Innovations in laser welding technology allow for nearly invisible joins between stones, creating seamless surfaces that appear as continuous fields of brilliance. These advancements have enabled designs previously considered impossible, from intricate geometric patterns at microscopic scales to fluid organic forms that mimic natural textures.

Beyond mere production efficiency, automated micro-setting unlocks new creative dimensions. Designers now experiment with stone arrangements that would have been prohibitively time-consuming to execute by hand. Gradient color transitions using hundreds of subtly different stones, optical illusion patterns that play with perception, and mixed-size settings that create texture variations—all become achievable through precise automation. This technology doesn't replace the jeweler's artistry; rather, it provides an expanded palette for creative expression.

The implications extend throughout the jewelry industry's value chain. For retailers, micro-set pieces offer distinctive products that stand apart in a crowded market. Consumers gain access to more affordable luxury items, as automated processes reduce labor costs without compromising quality. Perhaps most significantly, this technology makes exquisite micro-setting accessible beyond the realm of haute joaillerie, allowing fine jewelry brands to incorporate intricate detailing into broader collections.

As with any technological shift, challenges remain. The initial investment in micro-setting automation requires substantial capital, putting pressure on manufacturers to achieve sufficient scale. There's also the delicate balance between mechanization and craftsmanship—while machines excel at precision, human oversight ensures the emotional resonance that defines exceptional jewelry. The most successful adopters view the technology not as a replacement for traditional skills, but as a powerful complement that elevates the entire craft.

Looking ahead, the trajectory points toward even more sophisticated applications. Researchers explore ways to integrate AI-driven design systems that can suggest optimal stone arrangements based on light performance modeling. Other developments focus on hybrid systems that combine automated precision with hand-finishing techniques, preserving the human touch where it matters most. As these technologies mature, we may see micro-setting expand into entirely new categories, from watchmaking to architectural elements.

The 1mm gemstone automation revolution represents more than just a manufacturing breakthrough—it's a reimagining of jewelry's creative boundaries. By mastering the challenges of working at such minute scales, the industry opens doors to unprecedented design possibilities. What begins as a technical solution for placing tiny stones evolves into a new language of adornment, one that speaks equally to our love of precision and our desire for beauty that pushes beyond visible limits.

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025